|

|

|

|

Plastics 3D printing in FFF / FDM technology with plastic material is now affordable for everybody. The question arises, weather those 3d printed parts may be used as parts of load-bearing structures, especially for small structures in fair trade stalls, event construction, membrane constructions, in larger artwork, decorations, or for museum furnuture. Here quite often is a need for small unique joints and connectors, which are not available in the market. Forces are mostly low, and life time is often restricted to some weeks or month, which allows to ignore most considerations about environmental exposition, creeping and aging of the plastic material. |

|

structural.de works since January 2018 at FEA based and

methodically sound design methods for such parts. In litarature and research,

not many results are published yet. Serios filament manufacturers like

Ultimaker, Polymaker or Formfutura do issue data sheets with tensile strength

values, but all those values are tested in XY plane, means in printing layer

directions. Data tested perpenducular to the layer planes, i.e in Z-direction,

are not available. Only few companies, e.g. Stratasys and Polymaker, have published its strength values for

Z-direction as well.

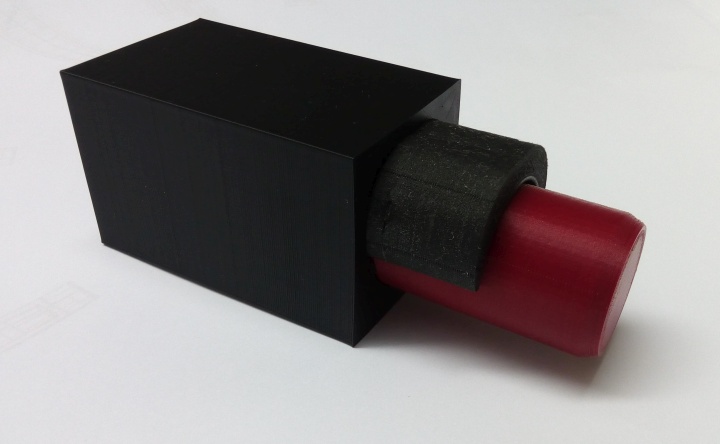

Standing printed specimen for tension test of ultimate Z-stresses |

|

It is widely known, that the tensile strenght in Z-direction perpendicular to

the printing layer plane is often much less than the one in XY-direction.

3d-printed parts in FFF / FDM plastic technology show a very clear orthotropic

behaviour. The problem is, that many functional parts have stresses in many

directions, and it is only in few situations possible to turn the part so that

major stresses run in the plane of the 3d printing process. So, we must live

with the fact that major stresses will most likely occur also in Z direction,

even if we try to optimize and even if we do the design stress check in FEA with

different stress limits according to the direction.So, the limit stress in

Z-direction will finally determine the usability of a material for load-bearing

functional parts.

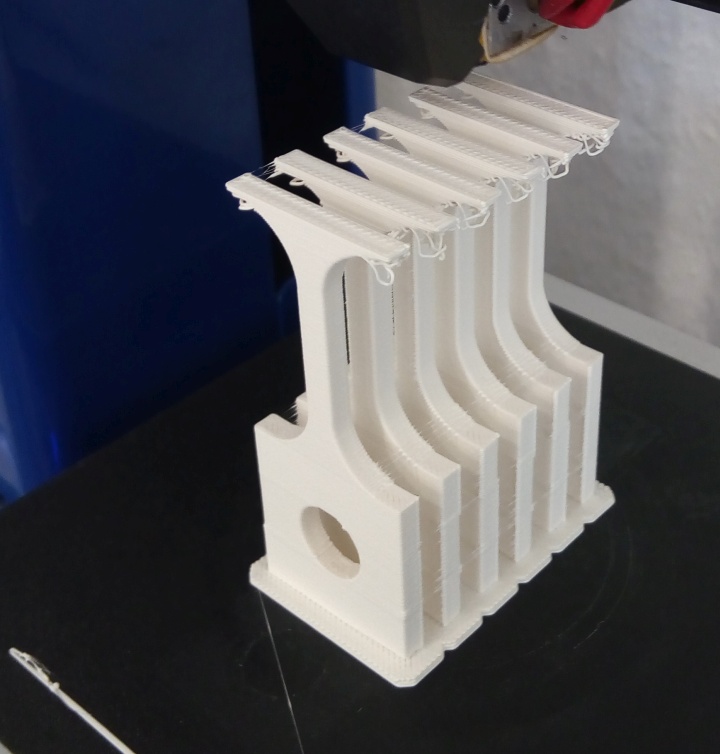

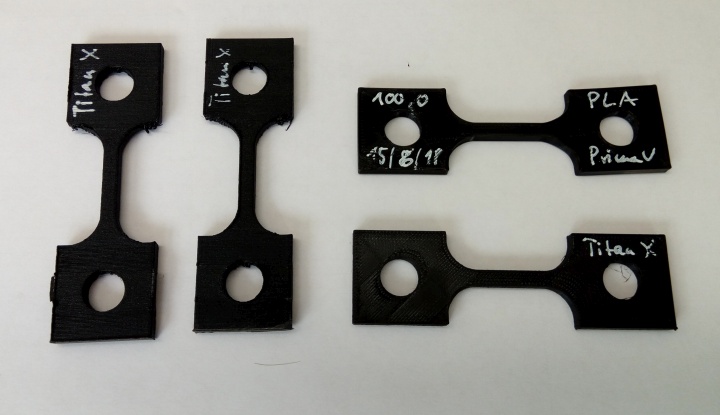

Therefore, hpl structural has done quite a lot of tensile strength tests for many different filament types in bot It just prints too ugly, warps too much, and strenght values are just average. Also the promising metal-based laser-melting and laser-sinter methods are still too expensive for our field of activities and had (yet) to be left out. |

|

With the ultimate tensile stress obtained from the

tensions tests, we are able to design the functional part as STL file, do the

structural analysis directly in our Strand7 FEA software, validate the limit

design stresses for the particular printer and material with the test specimen,

and finally produce the functional part directly on the desktop, at least for

test purposes.In this process, those materials turned out to be most

promising, which are easy to print, have a good melting behaviour, stick nicely

to the printing bed, have a good layer-to-layer adhesion, show no warping - and

- most important - show a ductile behavour (plasticity) before breaking. In terms of tensile stresses and ductility, we were very pleased with Polymaker PolyMAX PLA (Base: PLA) (as all PLA restricted to room temperature conditions) Polymaker PolyMide (Copolymer PA 6 / PA 6.6 „Nylon“)(indoor and outdoor use) Both materials are very ductile at least in its XY printing plane and have a relatively low difference between the tensile stress limits in XY directions vs. Z-direction. Interestingly enough,good printability turned out as a sign for good layer adhesion and good Z-.strength. But also the following fiber reinforced materials have impressed us, since they are very stiff (high Elastic Modulus) and have a very high tensile strenght in XY-direction: 3DXTech CarbonX Owens Corning / XStrand GF30PA6 (Glass fiber filled Polyamid) fiberthree F3 PA CF pro (Carbon fiber filled Polyamid) - with also a very good Z-strenght Those materials did not only show high stiffness and a very hight tensile strength in XY-direchtion, but also surprised with a very low warping even with 100% infill, which favourites them for high-performance parts acting like a plate. But even with those high-quality materials, and considering the common safety factors for plastic given by literature, the magnitude of the usable stresses is only about the same as of timber (5..16 MPa; SLS). This is admittingly not very much, but consider - you have a material without limits in geometry, and you can produce the part right now on the desktop! The plastic parts are also very useful for muck up models, functional and mechanism tests. Small 20mm² test specimen as STL-File Test results of 20mm² small specimen (Filament tensile strength results) Filament manufacturers or users of filaments suitable for load-bearing functional parts: Please feel free to send printed specimen (use STL file linked above) of your filament (minium 5 specimen in XY plane printed, minium 5 specimen in Z-direction printed) to hpl structural. Infill: 100% at +- 45 Degrees.; Bottom and Top Layer: 1 Layer. Edges: 1 Line. |

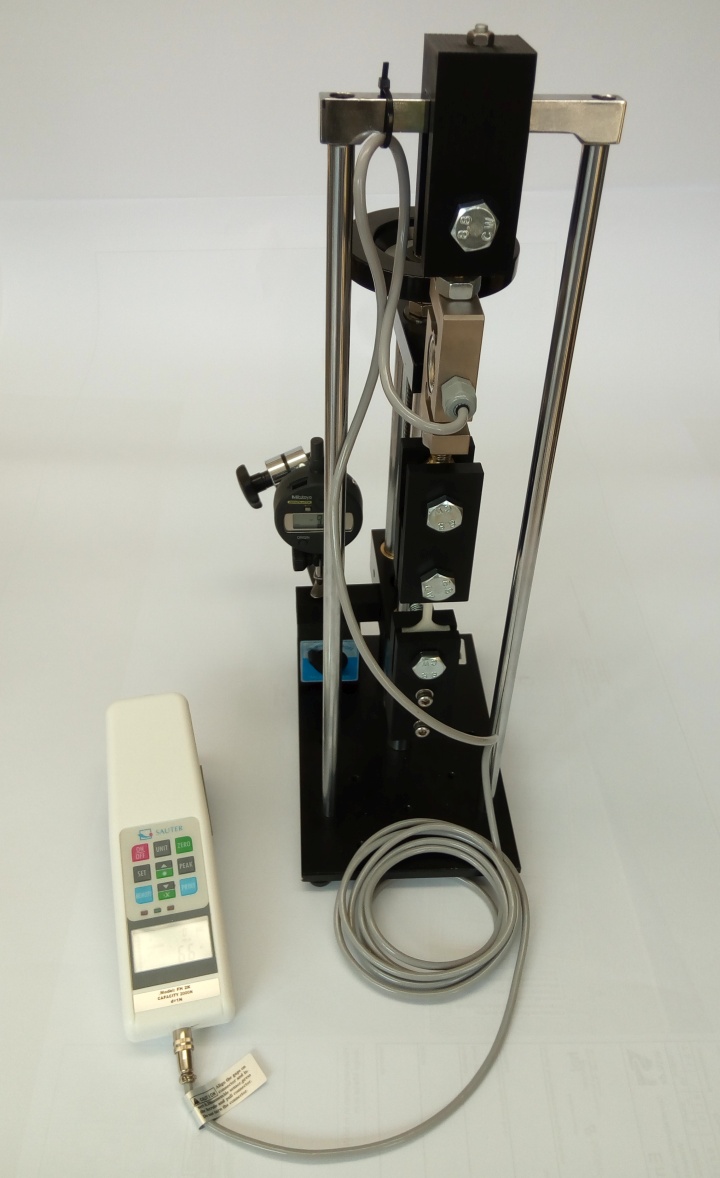

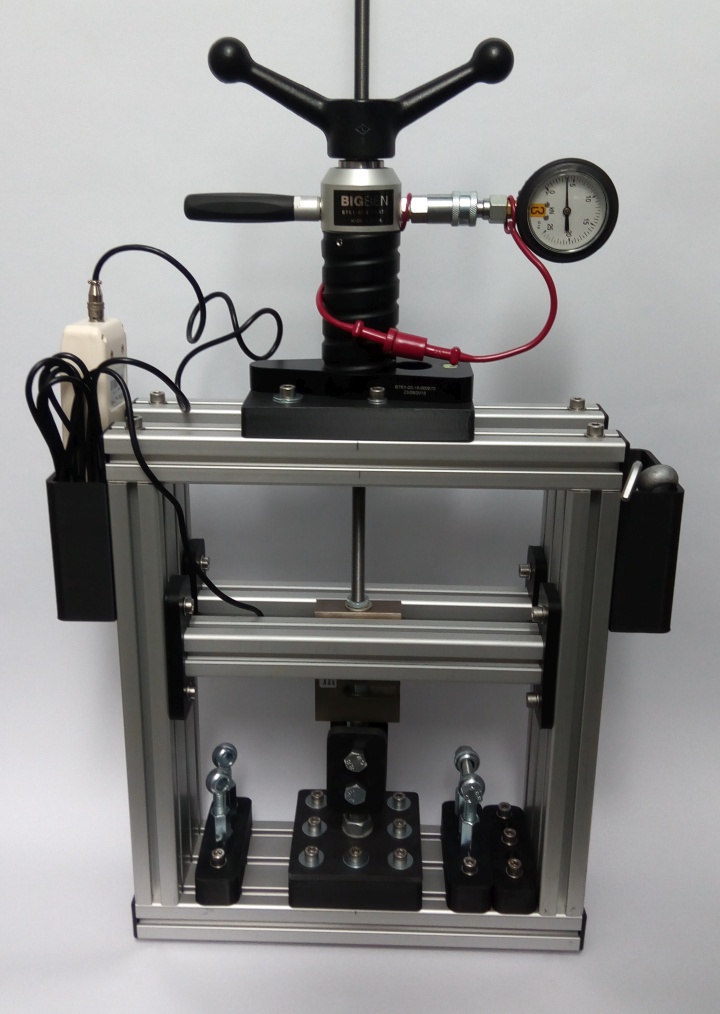

Small Specimen for strength tests Our present design method results for the plastics in a quite low usable stress level, due to the required safety factors for plastic and the limits of the material. The distance of the usable stresses to the breaking stresses is quite high. Therefore, we expect only a very low influence of creeping and aging for our purposes, as long as the ambient temperature is significantly lower than the vicat temperature of the plastic. To back this theses, we started middle term loading tests with typical stress levels of 5 MPa for periods of one to three month, the typical load duration times for fairground and event structures. Metall A very interesting alternative to plastic is the idea of 3d printed parts used as models for metal casting. Even with common cast aluminum alloys, the usable tensile stresses raise up to 10 times the value of the plastic part. And - for aluminum, the Eurocode 9 (DIN EN 1999) gives the engineer an officialy acknowledged code of practice for all the design work, also for large load bearing structures. All the known problems with plastics like aging, temperature and UV light exposition and creeping are simultaneously vanished. For this reason, structural.de tests a handy technology chain in cooperation with a local foundry. The disadvantage: The shape restrictions of both 3d printing and sand casting add up quite a lot. So, direct 3d printing in metall would be a dream. And now, it comes true also for small budgets! Since summer 2019, BASF Ultrafuse 316L metall filament is available! This filament contains about 20% POM plastic an 80% stainless steel powder (1.4404 - AISI 316L). You can print this in almost every common 3d printer, which is able to reach 100°C bed temperature and has a hardened steel nozzle. We had good success with our CreatBot F160, a 0,4 Microswiss hardened steel nozzle, 235° nozzle temp, 100°C bed temp, BuildTak printbed and Adimide adhesive. The green part is then sent to debinding and sintering at a service partners factory. The result: sintered stainless steel metal parts! BASF writes a yield strenght for the sintered parts of 230 N/mm² in its data sheets. Hardware A second test device allowing tension forces up to 20 kN will help to verify the theory at test part which are similiar in shape and size to the real structural part and for metal parts  Second test device for tension stress tests up to 20 kN |

| structural.de uses the

following printers for the test specimen and functional test part:

- Anycubic i3 Mega with Micro-Swiss wear-resistant nozzles and Ahltec Carbon Fiber printbed for fiber-reinforced polyamide - Anycubic Chiron for large-scale demonstration models in PLA and PETG - CreatBot F160 (Peek version) with Micro Swiss hardened steel nozzle, BuildTak buildplate, Adimide glue and chamber heating for BASF Ultrafuse 316L |

|

|

|

- 2019 - |

zurück zu: www.structural.de